The Seed

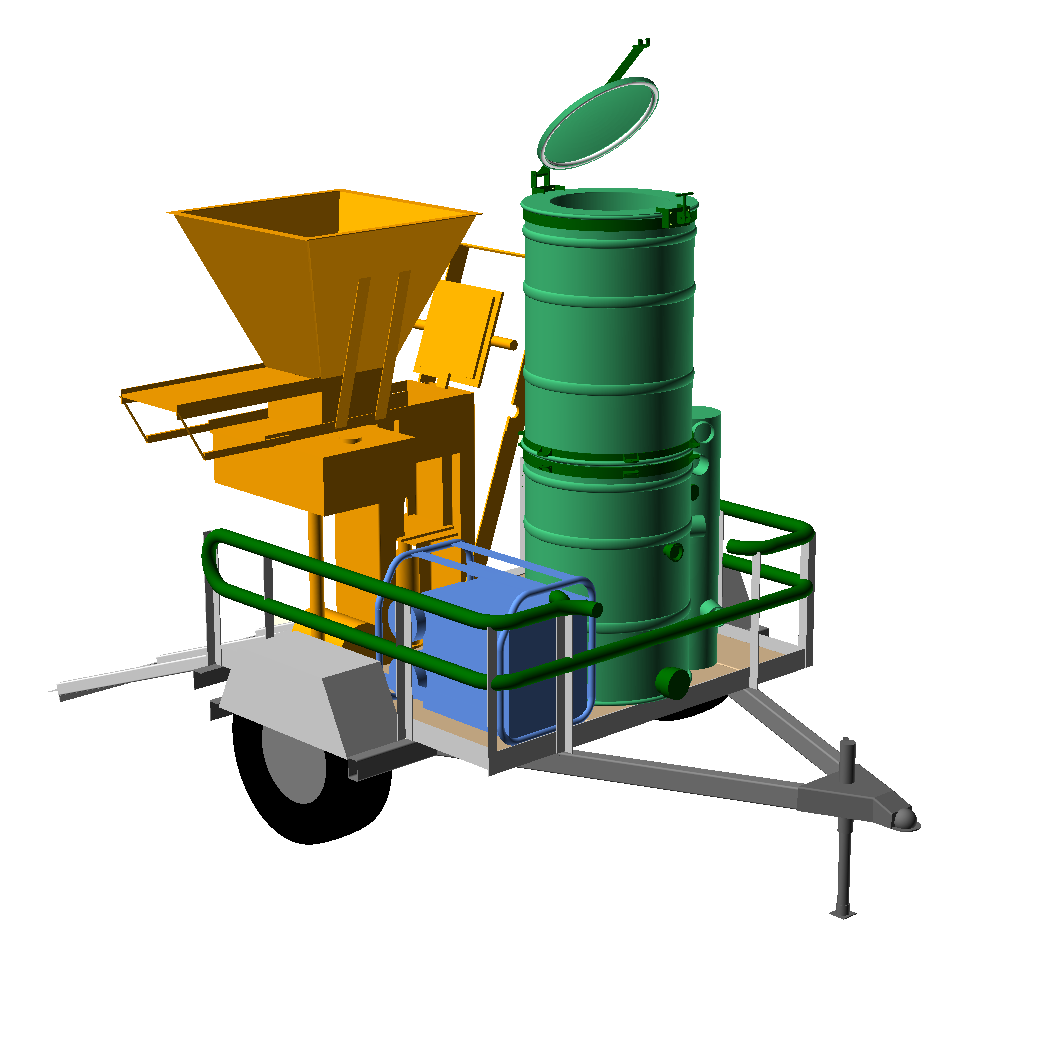

Solid Biofuel Gasifier GeneratorHydraulic Press

Carbon neutral fuel, electricity, and sustainable building materials.

Carbon neutral fuel, electricity, and sustainable building materials.

The Seed begins with the gasifier.

The test case is a 30' school bus converted to a self-sufficient living space.The gasifier needs to meet a range of daily needs: on-demand automotive fuel, stationary power generation, and heat for both air and potable water.The Seed will add a generator, a hydraulic press, and a trailer to facilitate a whole spectrum of uses.

A Scaled-Up Swiss Army Tool for Sustainable, Off‑Grid Living.

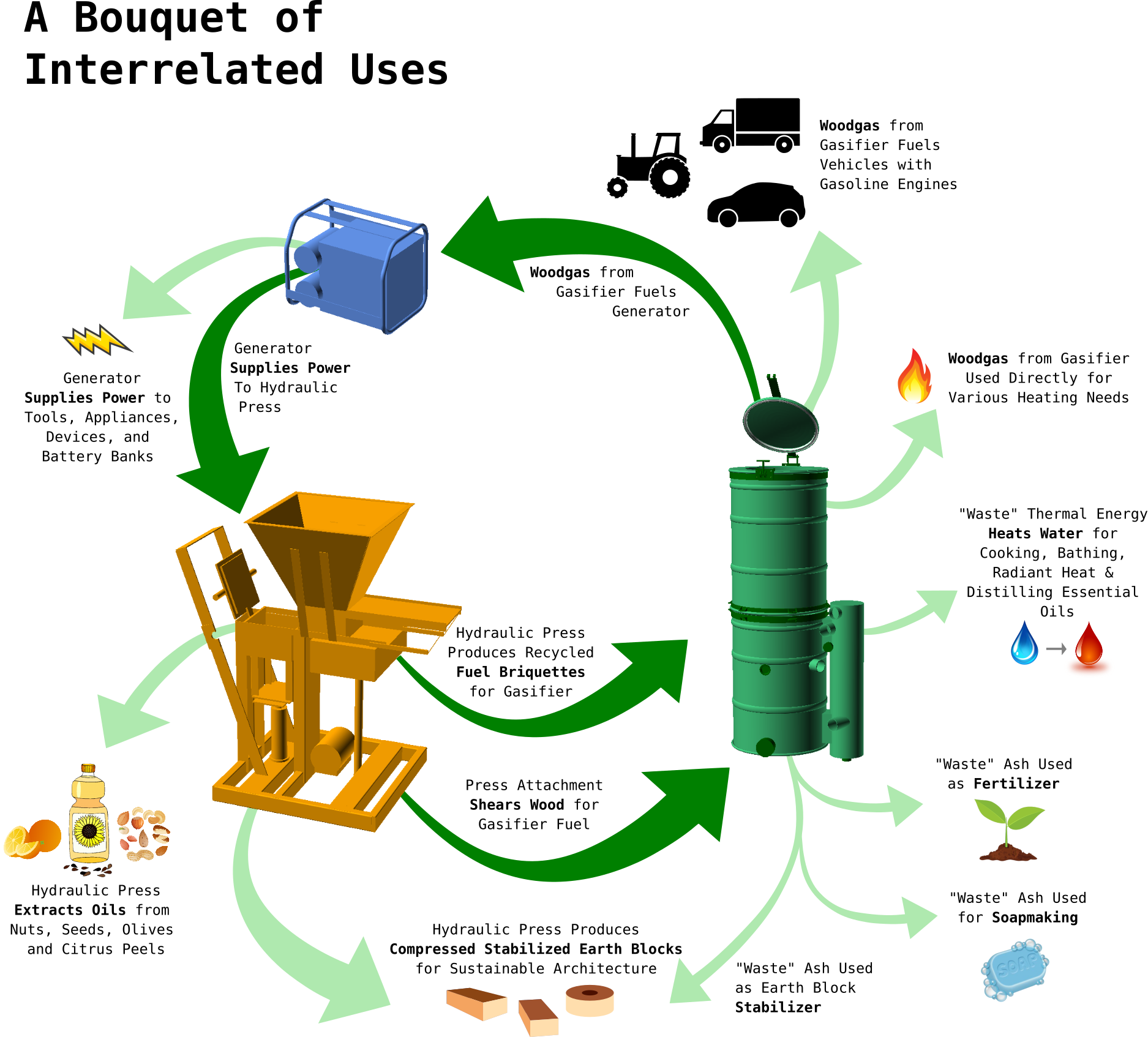

With a gasifier you can provide heat, drive your car, or run a generator using wood or plant waste for fuel. With a hydraulic press, you can create sustainable compressed earth block architecture, prepare a variety of fuel sources, and even press your own cooking oil from nuts and seeds. These technologies are not new, and there are many excellent examples out there for vehicles and homesteads alike. The novelty of this project is to maximize their useful traits for off-grid living, to make several innovations, and to put their respective "inputs" and "outputs" into as wasteless a synthesis as possible. Our goal is to make both research and final designs available to the public for Free under Open Source license! Designs are currently being developed, prototyped and tested. We're about 90% done with the fabrication of a prototype to be tested on a 7+ ton vehicle with a 7.4L/454cu engine.

A Step Towards Local

The Seed aims to cut reliance on Big Oil, grid electricity, and commercial building materials. The hope is that small communities can incorporate The Seed into their own self-sufficient models and contribute towards building networks for stronger local economies. When completed, The Seed will serve as an educational tool and segue to future projects.

It's Carbon-Neutral.

The gasifier uses biofuels, not fossil fuels. This means that the emitted carbon was already in the "fast carbon" cycle and would have been released into the atmosphere by the plant's eventual decomposition anyhow. This is different from oil, coal and other fossil fuels which rapidly release "slow carbon" that took our Earth millions of years to sequester.

But shouldn't we be planting trees, not burning them?

Yes! Planting a tree starts a life cycle of carbon sequestration. Cutting down a tree exposes decades, or even centuries of the tree's sequestered carbon to atmospheric reabsorption. It may not be adding to the "fast carbon" cycle like fossil fuels do, but it still disrupts the short-term carbon sinks of our living forests. More importantly, industrial deforestation is environmentally unsustainable and ecologically destructive. But you can make the gasifier carbon-neutral by sourcing fuel sustainably. Collect dead or dying wood, forestry waste, and industrial byproducts -- even cow dung! Why not? You can also create compressed fuel bricks using the hydraulic press! This opens the window to a much wider range of fuel materials; paper, sawdust, grasses, and blends of liquid biofuels.

Gasifier (re)Design Objectives

- Key points of improvements from existing gasifier designs:

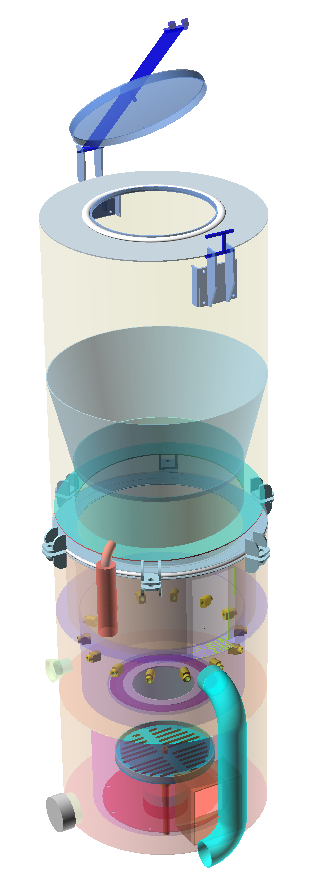

- A versatile reactor hearth that can perform adequately for both a 7.4L/454cu engine as well as for small generators and passive appliances running on a blower motor. This led to the design of a removable hearth insert.

- A digital system of sensors for better performance analysis. This entails Arduinos with touchscreen, five thermocouples, thermometer+barometer, GNSS module, and vacuum pressure gauges.

- Efficient use of wasted thermal energy: Exhaust gas cooling system meets the need to heat water. This has taken the form of an intercooler with auxiliary ports.

- Electrostatic precipitator for improved tar reduction and emission control.

Customizing the Hydraulic Press

Hydraulic presses are mechanical mainstays with endless practical applications across many fields. The challenge for The Seed is to facilitate several key utilities in one piece of equipment:

- press for fuel briquettes and compressed stabilized earth blocks

- insert for extracting oil from nuts and seeds

- wood shear for processing fallen branches and wood waste on the road

The press is still in the preliminary design phase. The rendering you see in the above images is a hybridized study of mass-produced Compressed Stabilized Earth Block presses. Future designs will be more efficient, compact and affordable to fabricate.

- Present design goals include:

- Compact and low profile design for maximized trailer bed efficiency and quick-and-easy setup

- Ease of interoperability - e.g. respective inserts for earth blocks, vegetable oil, and gasifier fuel preparation

- Easy hopper disassembly and durable enamel for sanitary transition between food and soil.

- Automatic control module for various use settings.

- Low overall weight

- Integration into trailer frame for stability and space efficiency, as well as possible removal from trailer altogether for standalone use.

That's it for now. Stay tuned, and thanks for your time and interest!